.jpg)

How Do You Wash a Tussar Silk Saree at Home

Mar 06 - 2024

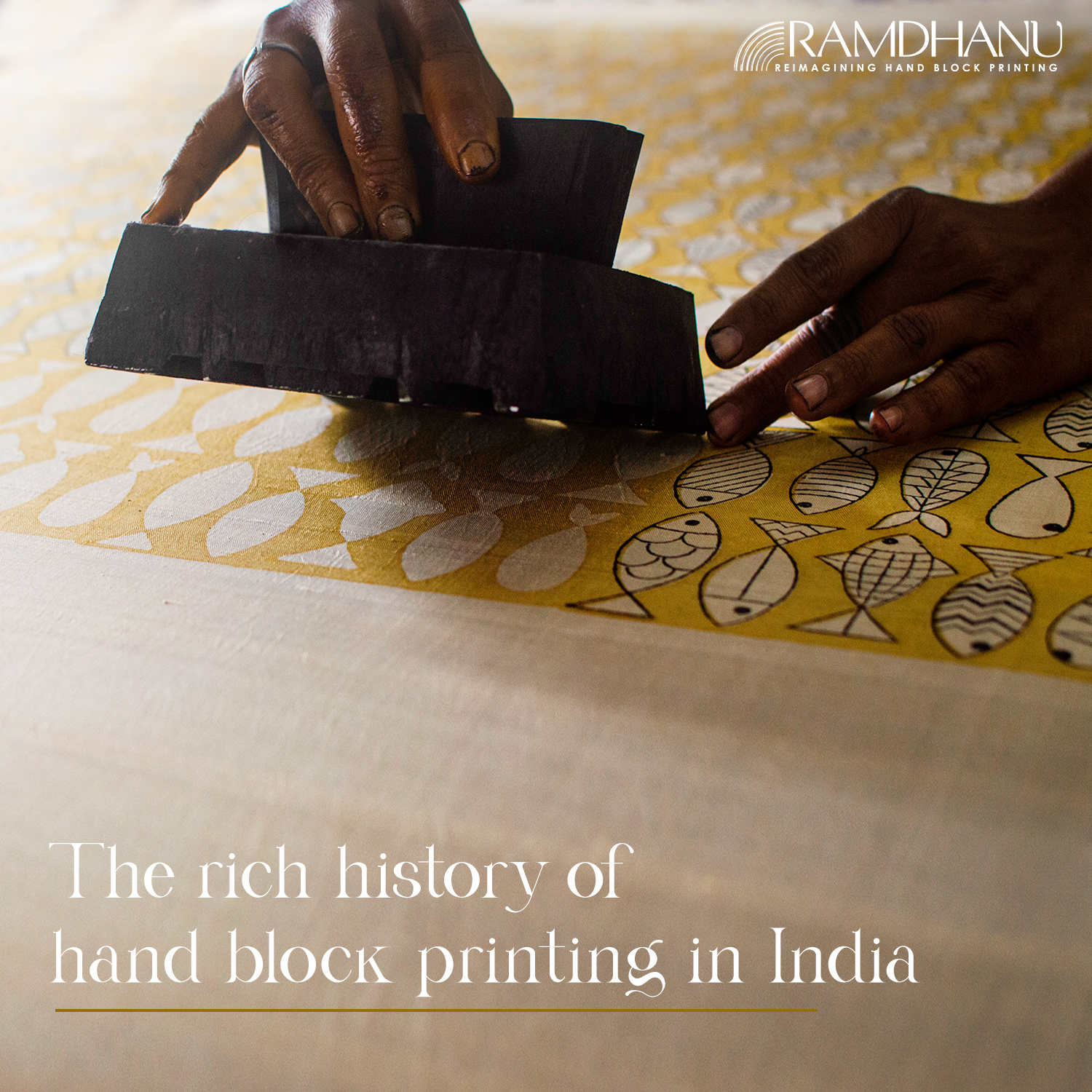

In India, the art of hand-block printing has a special place. The age-old practice of dyeing and coloring fabric by using wooden blocks has been popular among many artisans and fashion-loving people. The artisans have perfected it over generations. Each block print tells the story of India’s vast heritage and rich culture. India is one of the largest manufacturers and exporters of hand-block printed tussar silk sarees or any other fabric related to hand-block printing. Hence, it is important to discuss the history of this art form, its uniqueness, and how it’s being modernized today.

From the recorded history of the Indus Valley Civilization, we find the presence of hand-block print art. The Harappan period reveals the export of textiles. And during the Mohenjo-Daro site excavation, researchers found needles, spindles, and cotton fibers dyed with madder. This proves that the Harappan artists were familiar with mordants or dye fixatives. However, it is believed that the art form flourished in India during the Mughal period. Printing and dyeing of fabric originated in Rajasthan and was later adapted by Gujarat. However, in the present-day scenario, the art form is practiced in the states of West Bengal, Andhra Pradesh, Punjab, Maharashtra, Madhya Pradesh, and Uttar Pradesh.

The process of hand-block printing is very tedious. It takes 10-15 days to perfect. So, you can understand why printed pure silk sarees are always in demand. It starts with a fabric that is first washed free of starch. At this stage, tie-dyeing is done, only if needed. If the fabric is already dyed, then the fabric is washed to get rid of the excess color. After this, it is dried in the sun. The next step is the fabric pinned on the printing table.

Meanwhile, the artisans prepare the colors and keep them on a tray filled with glue and pigment binder to ensure a soft base for the color in order to allow it to easily spread on the block. The blocks are created using woods like teak, sycamore, and pear. These are hand-carved in a myriad of intricate designs that are first made using pencil on paper or chalk paste. After this, they get soaked in oil for 10-15 days to soften the timber.

When the blocks get ready, they are dipped in color and then pressed onto the fabric. This process gets repeated over and over again until the length of the fabric is complete. Artisans demand precision to ensure that there are no breaks in the motifs. And when there are multiple colors, other blocks are used, and the artisan waits for the first print to dry first.

Then the fabrics are left to dry in the sun. The next step is rolling the newspaper to prevent them from sticking to each other. The post-printing process starts with getting steamed, washed in water, and dried in the sun again, and finally, they get ironed.

There are three widely-used techniques of hand-block printing present in India. They are- direct printing, resist printing and discharge printing. In direct printing, the fabric is first bleached, then dyed, and finally printed using carved blocks. In resist printing, artisans make sure some areas of the fabric are protected from the dye, which is shielded with the use of any clay and resin. Then the dyed fabric gets washed, but the dye spreads through the protected areas which cause a ripple effect. The last is discharge printing. In this technique, chemicals get removed from the dyed fabric which is then filled in with different colors.

Hand-block printing is a labor-intensive job that catches everyone’s attention. From carving wood to making a block to transferring an impression onto a textile surface, it is the work of humans that create little variations and imperfections which are imperfect yet charming. It is also a versatile and sustainable technique. When you search printed silk sarees with a price on Google, you definitely find our sarees which are a testament to the art of hand block printing. We, at Ramdhanu Ethnic, believe in the power of handloom products. In this era when everything is dominated by machines and business owners look for mass production, we focus on creating sustainable products crafted by hand. We also focus on the intricacy of the art form. Our master craftsmen ensure the fineness and depth of the prints.

The main focus of our work is to create printed tussar silk sarees or any sarees with a contemporary aesthetic. We use natural organic dyes, colors, and eco-friendly techniques to produce our sarees. We've been working with traditional hand-block printing for quite a time now. Block printing is an integral part of our journey as a fashion brand. Our artisans make sure that each motif is brought alive as envisioned. They ensure an interplay of handicrafts and rich colors. The amount of time and care taken by our master artisans make each product not only special but also a collectible item.

Hand-block printing is a traditional art and people follow it for a very long time, as discussed previously. The designs and art forms that originated from hand block printing are considered the most popular and best all over the world. The hard work and energy of artisans add a cultural and trendy vibe. If you see any printed tussar silk sarees or any sarees, you can see the various sub-art forms of block printing. They are Bagru printing, Ajrakh printing, Kalamkari block printing, Dabu printing, and Sanganeri prints. These types of sub-art forms have gained popularity over the years and are widely used in the process of manufacturing different types of textile products. Along with normal designs, traditional hand block print designs include designs of small flowers, various motifs, and bootis. Mughal designs are also popular. Designs like elephants, and luxuriant flowers are heavily used in printed pure silk sarees or any saree. These are very popular in India for a long period of time. Hence, hand-block printing requires proper artwork, experience, and knowledge of the artisans to create a wonderful and artistic piece of hand-block printing designs and sustainable edits.

During British rule in India, the beautiful art of hand-block printing started to fade away because of the heavy taxes levied on Indian textiles by the Britishers. Owing to this, many artisans from rural India gave up creating sarees with hand-block printing art. Later, they migrated to cities to work in cotton mills.

However, after independence, the government of India launched various schemes to support the craft and its artisans. Some of the schemes were directly aimed at the block-printing craft.

The foundation of institutes like the National Institute of Design (NID) & National Institute of Fashion Technology (NIFT) has helped in spreading awareness about this art and craft. Students now collaborate with artisans on projects related to design, marketing & promotion. Over the years, big design houses to small designers within the industry have worked with the craft to create contemporary designs which make it relatable. Because of all these efforts, India has seen a resurgence of this craft in modern times.

Visit Our Stores:

Jodhpur Park: 1/420 GARIAHAT ROAD SOUTH, SELIMPUR BUS STOP, KOLKATA- 700068 LANDMARK- OPPOSITE TO CARMEL CONVENT SCHOOL

https://g.page/r/CdDnnZnwqHV8EA0

Salt Lake: BE-01 SECTOR-1, BE PARK, SALT LAKE, KOLKATA- 700064 LANDMARK- NEAR KWALITY CROSSING

https://g.page/r/CWmIg0TFU7wOEA0

You can find us on almost all social media platforms. There we upload images and videos of edits on a daily basis. Make sure you follow us there to get the latest updates.

Facebook: https://www.facebook.com/ramdhanuethn

Instagram: https://www.instagram.com/ramdhanueth

Twitter: https://twitter.com/Ramdhanu_Kol

Pinterest: https://in.pinterest.com/ramdhanuethn